Towel:

Non-Stop Toilet Paper Kitchen Towel Rewinding Machine Description:

Toilet paper full embossing roller slitting rewinding machine is to perforate and cut the raw paper into various sizes according to the requested. The finished product is neat, in good order and with equality tension. It has the feature of compact structure, easy and stable operation, less electricity consumption and covers a small area. The highest production speed is 200-350M/min.

It has HMI, Chinese-English switch; synchronous frequency conversion drive;integration of mechanics, electrics and photo. It is equipped with whole trouble information. It can detect and adjust every action of the rewinder automatically to keep the rewinder in optimal situation.For example:There is a web tension system in the line,It can control speed according to the tension of web so it can adapt different type of jumbo roll.So it is the best choice to produce top-grade bathroom tissue and kitchen towel for paper company.

It uses Programmable Control System, frequency converter to adjust speed, electronic brake and HMI. There is a mechanical speed adjustment for unwinding back stands which is based on the stretching and tension of the raw paper Enable the equipment to operate under optimal condition. Gluing blade system is used in F-20 tail sealer: the system perfectly improves the sealing of tissue roll and reduces glue waste, making machine easy to clean and maintain. Accumulator: When accumulator is overloaded or undersupplied, it will automatically stop.The equipment has the function of reel breaking and reel end detection, equipped with automatic alarm, decelerating and stop device.

Adopt PLC control system it’s easy to operate. When the core unit can not detect core or core will use up, the machine will alarm to tell operator or workers to put some cores on the core bracket. Degree of tightness can be adjusted while a log is rewinding. It can produce different degree of tightness in one log. When a log is rewinding the next core is ready. When the finished log come to tail sealer, trimming. glue spraying and sealing can be finished at the same time. Embossing unit and glue lamination edge embossing unit, printing system is order by customer. Independent wall-type backstand, stucture is simpler and stronger, easy to clean.

Main Features and Advantages:

1) Unwind is equipped with closed loop frequency conversion control system.

2) When the webs do not align,you can operate on the touch button screen to move the jumbo roll till webs align.

3) When the core unit can not detect core or core will use up, the machine will alarm to tell operator or workers to put some cores on the core bracket.

4) When the machine is running,web break off suddenly for reason of speed change sharply of problem from jumbo roll.

5) Degree of tightness can be adjusted while a log is rewinding.It can produce different degree of tightness in one log.

6) When a log is rewinding,the next core is ready.

7) For the reason of using advanced technology:Program Logic Control System; synchronous frequency conversion drive;integration of mechanics,electrics and photo.

8) The perforation roll of the rewinder is machined by high precision numerical control milling machine.It is one-up in the world.The perforation blade come from Germany and it can produce well-proportioned perforation with low noise and long life.

9) When the finished log come to tail sealer,trimming,glue spraying and sealing can be finished at the same time.

10) Embossing unit and glue applicator edge embossing unit printing system is order by customer.

Machine Performance and Parameters:

Machine Model | 2800/2900/3600/4000/4300 |

Width of Parent Roll | 2750/2850/3550/3950/4250(mm) |

Working Speed | 350m/min |

Dia. of Finished Roll | 90-150 |

Dia. of Parent Rall | 1500, 2000, 2500, 3000 |

Inner Dia. of Parent Roll's Core | 76.2 (customized) |

Perforation Pitch | 120mm (Adiustable, other size please specify) |

Programmable Controller | PLC computer programming |

Count Mode of Paper Roll | by the diameter or sheets amount |

Glue Laminator | point to point,decorative embossing |

Unwinder | 1-4 ply(customized) |

Motive Power | 90-150 KW |

Details:

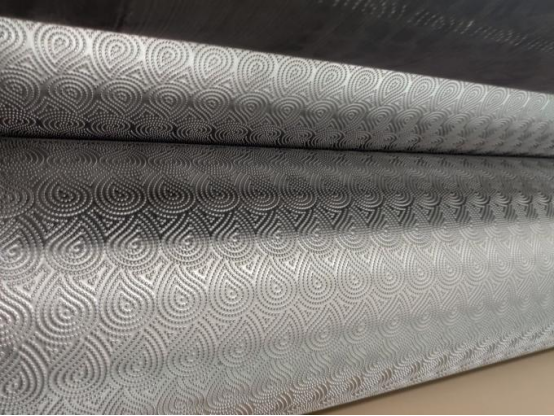

Full embossing device

This embossing unit can engrave the pattern without color, the diameter of roller is 240mm, and the pattern is engraved by computer, it it very clear and regular.

Jumbo roll stand:

Independent wall-type jumbo roll stand, structure is simpler and stronger, easy to clean. It is controlled by the independent frequency motor, and the tension is tracked by the encoder.

Glue lamination device:

This glue lamination unit can add colors, but one glue lamination can only engrave one kind of pattern, the diameter of the embossing rollers are 394 mm. And the pattern is engraved by computer, it it very clear and regular. Pattern can be any logo, words, flowers,etc

Real machine model:

1 rewinding unit + 1 glue lamination unit + 2 full embossing units + 2 jumbo roll stands