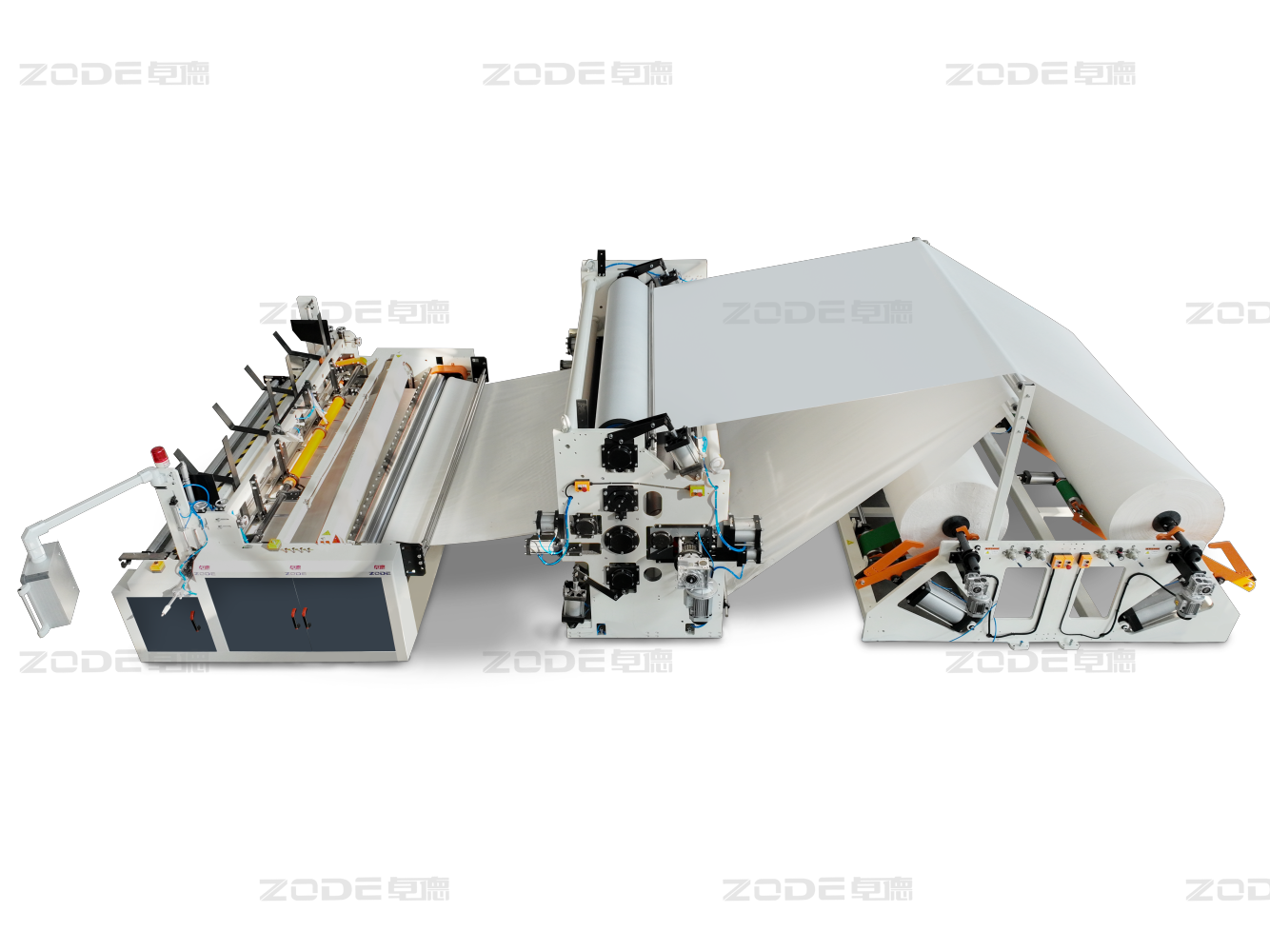

Automatic Toilet Paper Kitchen Towel Rewinder Machine Description:

This is the Complete production line for toilet paper and kitchen towel. From the rewinding machine, cutting machine to packing machine.

This equipment is adjustable to meet the requested finished product of toilet paper and kitchen towel. This model is the ideal equipment for paper making factory and paper converting factory.

This equipment is to perforate and cut the raw paper into various sizes according to the requested. The finished product is neat, in good order and with equality tension. It has the feature of compact structure, easy and stable operation, less electricity consumption and covers a small area. The highest production speed is 200-250M/min. This equipment is adjustable to meet the requested finished product. This model is the ideal equipment for paper making factory and paper processing factory.

We have 2000mm,2200mm,2800mm,3000mm and so on , we have different machines to meet different budget, not only for big companies but also for small business.

Main Features and Advantages:

It has HMI, Chinese-English switch; synchronous frequency conversion drive;electrics and photo. It is equipped with whole trouble information.

1.Adopt PLC control system, it's easy to operate.

2.When the core unit can not detect core or core will use up, the machine will alarm to tell operator or workers to put some cores on the core bracket.3.Degree of tightness can be adjusted while a log is rewinding.It can produce different degree of tightness in one log.

4.When a log is rewinding,the next core is ready.

5.When the finished log come to tail sealer, trimming, glue spraying and sealing can be finished at the same time.

6.Embossing unit and glue lamination,edge embossing unit,printing system is order by customer.

7.Independent wall-type backstand, stucture is simpler and stronger, easy to clean.

Machine Performance and Parameters:

Rewinding Machine | |

Model | 2000/2800/2900/3000mm |

Jumbo roll width | 1930/2150/2750/2850/2950mm |

Jumbo roll diameter | ≤ 1200mm (other size to be specified) |

Jumbo roll core size | Dia:76mm (other size to be specified) |

Finished roll diameter | Dia:60-130mm(Tightness is adjustable) |

Finished roll core diameter | Dia:32-50mm |

Perforation width | Standard size:110mm(Adjustable) |

Perforation | 4 PCS sprial upper perforation knives,improve the durability |

Rewind type | Automatic rewinding machine |

Parameter set | Touch Screen HMI |

Rewind system | With core and coreless integrated |

Control system | Siemens PLC,inverter,etc. |

Machine speed | 200-250m/min |

Backstand | 1-4 ply (to be confirm by client), independent drive |

Edge embossing unit | Steel to steel |

Glue Lamination unit | Available (to be confirm by client) |

Embossing unit | Steel to steel, steel to rubber (to be confirm by client) |

Details:

1)Jumbo roll stands

Lamination Embossing unit

Sample